Optimize logistics by automating the distribution dispatch process

Challenges in trucking logistics abound. Here are some of the key issues:

- A growing volume of goods, driven by increasing online trade

- Supply chain disruption

- Growing competitive pressures

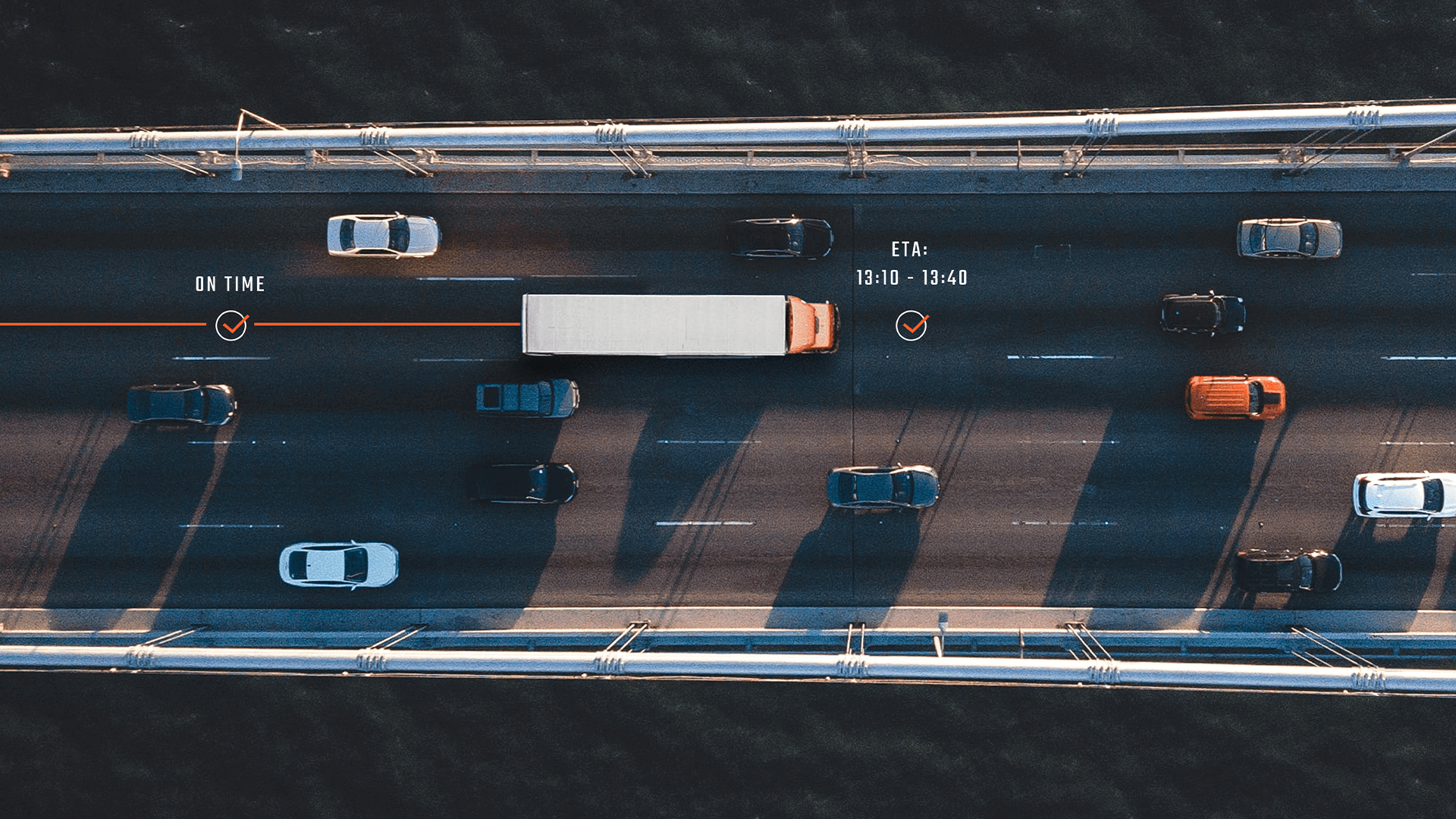

- Traffic increasing everywhere

- High costs of energy and fuel

- Shortage of skilled dispatchers

- Shortage of drivers

All these factors put pressure on logistics managers to maximize the efficiency and profitability of their trucking operations. Finding smart ways to optimize the dispatch process can leverage significant hidden potential. To get there, you need to take a closer look at these questions:

- How efficient and effective is my approach to dispatching?

- Are my vehicles and drivers being utilized well, or can we optimize utilization?

- Can any manual planning activities be automated and optimized?

- How can we raise our customer service level and improve timeliness?

- How can I overcome the shortage of skilled labor?

In short, the question is: Where and how can you lower costs while leveraging hidden potential to be more attractive to customers and job seekers? It is possible to achieve all of these objectives by digitalizing and automating your dispatch process!

What dispatch automation can do for you

The core objective of automating the dispatch of multidrop deliveries is to streamline trip planning and optimization. It enables day-to-day automated and optimized management of haulage orders (deliveries, pick-ups, direct trips) across a configurable fleet.

A haulage schedule is considered ‘optimized’ when all orders have been assigned to the available vehicles and drivers in a way that is efficient, with all applicable constraints accounted for automatically. Typical constraints include:

Parameters for dispatching

- Departure and return times of individual or all vehicles from/to the depot

- Time windows at shipper and consignee sites, distinguishing between deliveries and pick-ups

- Compliance with legal regulations for driving and resting times

- Differentiation between light and heavy local transportation for automated allocation of freight items at the warehouse

- Planning of multiple trips and repeated loading

Fleet

- Vehicle types, capacities and extra equipment

- Flexible definition of servicing areas and variable assignment of vehicles or vehicle types to areas

Freight-related parameters

- Parameters for computing the required warehouse space based on dimensions and packaging codes

- Mapping of additional order attributes, such as product codes, to planning parameters, e.g. time windows and priority

Smart, automated optimization tools not only get carriers ready for the future but also help them optimize various processes, haul goods efficiently and sustainably, and create modern, attractive jobs.

Smartlane has designed Smartlane Transport Intelligence, an AI-based, innovative software solution, specifically to meet these requirements